深圳市通意达电子有限公司

地址: 深圳市南山区留仙大道创智云城A7栋10楼

电话: 86 - 755 - 86216033 - 202

传真: 86 - 755 - 86051857

网站: www.tyd-ele.com

邮件: nerrissa@tyd-ele.com

mark@tyd-ele.com

邮编:518000

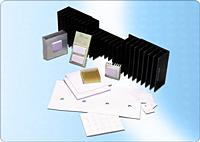

Tflex 600

Tflex 600 Series

Thermal Gap Filler

EXCEPTIONALLY SOFT, HIGHLY COMPLIANT GAP FILLER

Tflex 600 is an exceptionally soft, highly compliant gap filling interface pad with a thermal

conductivity of 3 W/mK. These outstanding properties are the result of a proprietary boron

nitride filler in the composition.

The high conductivity, in combination with extreme softness produces incredibly low thermal resistances.

Tflex 600 is naturally tacky and requires no additional adhesive coating that can inhibit thermal performance. Tflex 600 is stable from –45°C to 200°C and meets UL 94 V0 rating.

STANDARD THICKNESSES 0.020 to 0.200-inch (0.5 to 5.0mm) 0.020 to 0.200-inch thick material available in 0.010-inch (0.25mm) increments Inquire about availability of material and options above 0.200-inches STANDARD SHEET SIZES 9 x 9” (229 x 229mm). 18 x 18” (457 x 457mm). 9 x 9” only over 0.100” thickness. TflexTM 600 can be die cut to individual shapes. Pressure sensitive adhesive is not applicable for TflexTM 600 products. TACKY ONE SIDE ONLY Tflex™ 600 is naturally tacky on both sides. Tflex™ 600 can be provided tacky on one side only. This is indicated by the suffix “DC1”. This option offers good separation properties allowing the tacky side to stick to the heatsink/chasis/cold plate/etc. and the other “dry” side to release easily from the component(s). REINFORCEMENT Fiberglass is required in 0.020” (0.51mm) and 0.030” (0.76mm). Thicknesses of 0.040” (1.02mm) and above do not require reinforcement. Data for design engineer guidance only. Observed performance varies in application. Engineers are reminded to test the material in application.

More Information:

http://www.tyd-ele.com/0/www.tyd-ele.com/upload/2019/11/21/20191121101617393.pdf